O Tatou Hoa

about us

Inspired by indigenous thinkers.

Aotea was founded in 2017. We are inspired by mātauranga Māori (Māori knowledge) and this knowledge manifests itself in our range of therapeutic skincare. Aotea is the Māori name for Great Barrier Island, it is our namesake, and where we are from. It is here that we grow all the native flora that we use in our range, we extract the active compounds and use these healing extracts for the key tenants in our products.

We have a commitment to our values and culture. These are the pillars for our business. In light of which, we have elected, despite the difficulty to manufacture our entire range on our papakāinga (land). This allows us to create jobs in our community. Further, we are proud to say that it is our fourth year providing scholarships to our rangatahi Māori on Aotea to attend high schooling in Auckland, as there is no high school on Aotea.

This thinking pervades our direction and what we are as a business. Two things we are investing into significantly is the research and development attached to our products and flora, as well as having a completely circular economy where waste is designed out. We are building onto our existing solar farm so we the operation of our facilities are completely carbon neutral; and our product has a minimal carbon footprint.

About the island, Aotea.

Aotea, also known as Great Barrier Island, is the 6th largest island of NZ with an area of 285 sq kilometres. It is where we make your products and it is also our namesake. Māori named the island Aotea meaning white cloud (ao – cloud, tea – white) as it appeared in the distance as a white cloud on the horizon. Aotea is also the name for one of great seven migratatory voyaging waka.

Despite its stunning natural beauty, its relative remoteness means it has remained unspoiled and a haven for native birds and plant life. Aotea is even free of some of the introduced pests which plague ecosystems in other parts of the country.Standing at the entrance to the Hauraki Gulf 100 kilometres NE of Auckland, its 43 kilometre long coast protects the inner waters of the Hauraki Gulf from Pacific Ocean storms, hence in 1769 Captain Cook giving it the European name, Great Barrier Island.

Today the Māori people of the island are Ngāti Rehua, a hapu (sub tribe) of Ngāti Wai and their connection with the island can be traced back hundreds of years.

Our Research and Development

We are investing into the necessary R&D of the healing flora of this country; we aim to be the first in the world to critically extract the lipids and terpenes, the healing plant chemicals found in kawakawa and kūmarahou. This will allow us to undertake clinical trials and tests to give more credibility to our anecdotal history.

The supercritical extraction method is a new separation technique developed in recent years. It is used to extract and separate substances using a supercritical fluid as a solvent. When something is supercritical, it means that it has the properties of both a liquid and a gas. This is advantageous because CO2 can reach into small spaces like a gas but can also dissolve and act like a liquid solvent.

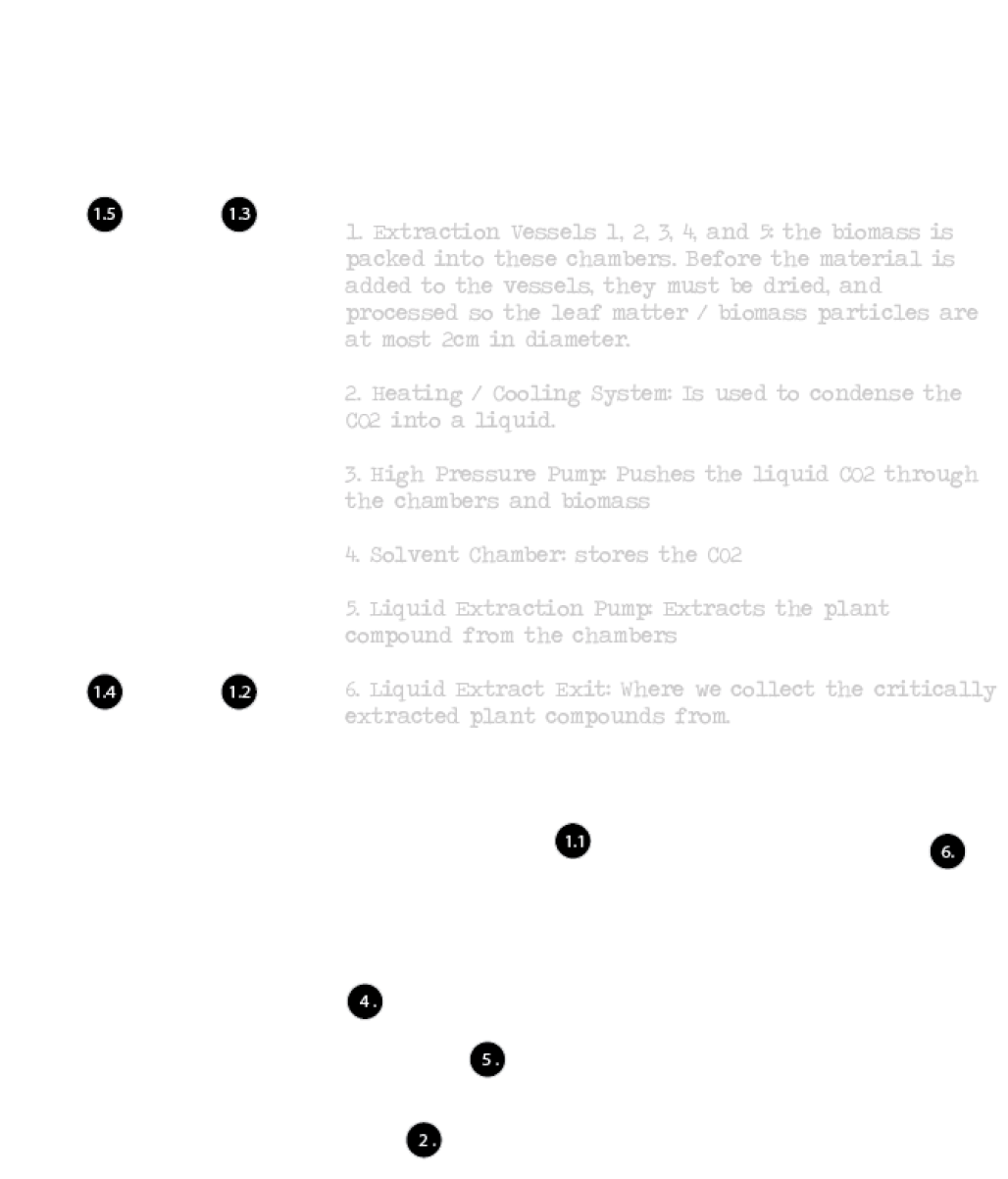

To perform an extraction, the plant material must be ground and placed into an extraction vessel. CO2 gas undergoes temperature and pressure manipulation. This turns the CO2 into a liquid and makes the CO2 supercritical. A pump then forces supercritical CO2 into the extraction vessel where it meets the plant biomass and breaks the trichomes and plant compounds allowing it to dissolve part of the plant material. A pressure release valve then allows the material to flow into a separate vessel, where an internal compressor and heater are used to adjust pressure and temperature. By changing the temperature and pressure as well as flow rate, certain molecules will bond to CO2, allowing them to be separated from the plant. Many systems will reroute CO2 back into the tank to be used during the next batch. The extract is then moved to a collection jar, such as a beaker.

Not only does this allow for a more precise method of extracting these healing plant chemicals, but this extraction process does not involve the heating of the biomass to extract the plant chemicals. This means, importantly, these plant agents are not denatured, meaning they retain their capacity to be incredibly healing. Virtually all extraction methods involve some use of heat.

Further, by using supercritical CO2, the producer has total control over the procedure, CO2 can be recycled, making this method more environmentally friendly compared to others. Further, the Federal Drug Administration (FDA) has labeled CO2 safe for industrial extractions. CO2 acts as a cleaning agent, so microbial bacteria, molds, and mildews are killed during the process. The yield using supercritical CO2 is higher than other extraction methods; however, the yield and quality of product can easily be varied by adjusting the physical properties.

If there is residue on the extract, it will evaporate, as CO2 is a gas at room temperature. Extracts obtained from supercritical CO2 extraction are appealing to the food and beverage and medical industries, because it is guaranteed there is no residual solvent present on the product. Because there is no residual solvent on the product, the extract will be purer than many solvent-based extraction methods. Additionally, the plant is not subjected to extreme temperatures, so it does not experience degradation as it does during other extraction methods.

Supercritical carbon dioxide is a widely used extraction method in the cannabis industry due to it effectively purifying the crude plant material. When CO2 is used in a supercritical state, it allows the producer to always be in control of the process by manipulating its physical properties to isolate certain molecules. We are applying this extraction method to some of the native plant flora of Aotearoa and we look forward to sharing what we discover, with you.

Our commitment to a Circular Economy

What is a Circular Economy? The products we use for all aspects of life are often designed and manufactured with little thought for the resources consumed in making them or what happens to them at the end of their life. Apart from the most expensive purchases we make, like a car or house, when something breaks in our modern world it is often more expensive to repair than to buy a new one, and usually it goes to the landfill. Simply put, these products are not designed for reuse, repair, refurbishment or to be remanufactured. This take-make-dispose mind-set has created a linear economy. A circular economy is an alternative to the traditional linear economy in which we keep resources in use for as long as possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each service life. When a product is designed for the longest use possible, and can be easily repaired, remanufactured or recycled (or used, composted and nutrients returned) we consider it to have a circular life cycle.

A circular economy is fueled by renewable energy (eg solar, hydro, wind and tidal power, and biofuels), and waste in the manufacturing and processing of a good or service is either minimised or designed entirely out.

A linear economy

A linear economy traditionally follows the “take-make-dispose” step-by-step plan. This means that raw materials are collected, then transformed into products that are used until they are finally discarded as waste. Value is created in this economic system by producing and selling as many products as possible

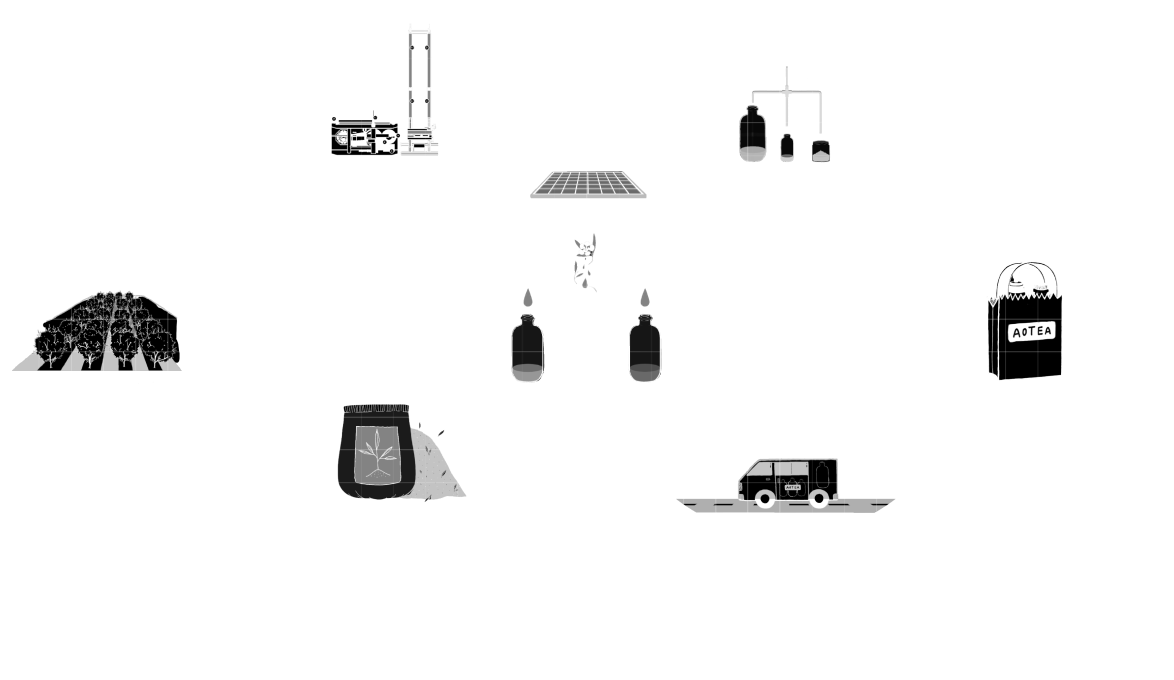

The Aotea Circular Economy

We see the world through an indigenous lens. Consequently, a circular economy is very consistent with the principles of Te Ao Māori.

In kind, we have designed a business model that allows for a true, circular economy.

Our extraction and production, manufacturing and packing facilities are powered by solar. We use the leftover biomass of flora from the extraction process to feed our crop of mānuka, kawakawa and kūmarahou. Our distillery is very water intensive, to guard against water loss, we now pump the water used in our condensation column, back into a holding tank to be reused, and any grey water from the production facility is used to go onto our crop to water them.

Further, we are pleased to be introducing a closed loop for our packaging. We will be offering the option for our direct to consumer customers (through our online channels and through our shop) to return the packaging, so we can take the packaging, for them to be sterilised, repacked and ultimately reused. Every year in the beauty industry, over 300million tonnes of waste is created every year; half is discarded after a single use, with a staggering 120billion cosmetic packages yearly. Although small, we are proud to be contributing to a more circular future.

Aotea Solar Blueprints

We are dedicated to achieving our goal of having energy resilience, and being powered entirely by solar in the manufacturing and operation of our production facilities. We go into our plans and blue prints for our solar farm below.

Sunlight is an electromagnetic field that travels through space. It contains photons which have no mass, and no electric charge. When these photons hit a photo-voltaic (solar) cell, they knock free an electron in the top layer of the solar cell. This ‘free' electron is is then routed as electricity to do work, like powering a machine.

The solar cell itself acts a semi-conductor. This means that when sunlight is not hitting the solar cell it is an insulator, and doesn’t conduct electricity. That is, the solar cell will not work as no electrons will be moving.

When sunlight does hit the solar cell, the energy of photons (sunlight) hitting the solar cell means that electrons can move around. It will then act as a conductor of electricity. The chemical reasons for this are below:

(1). A solar cell is made of two layers of silicon, the top layer is doped with a chemical called Phosphorus (doping meaning Phosphorus has been ‘added’ to the silicon). The bottom layer is doped with a chemical called Boron. Phosphorus has 5 electrons, where as Boron has 3. Silicon has 4 electrons. Because the top layer has more electrons it has a latent negative charge, relative to the bottom layer, which has a latent positive charge (it has less electrons because of the addition of Boron). So we call the top layer N-Type, and the bottom layer P-Type; negative charge, vs positive charge.

(2). The consequence of adding an extra electron per atom to the top layer of the solar cell means that when photons (sunlight) hits the solar cell, it gives the extra electrons energy to move around freely. However, it won’t act as an electric current unless it has a home to go to; like magnets, positive and negative charges attract one another. So remember, the bottom layer has less electrons.

With less electrons, there will be ‘holes’ where there would ordinarily be an electron, so that bottom layer will be positively charged because it is missing an electron. This relative difference between the two layers creates an electric field. And when sunlight hits the solar cell (giving energy to the electrons on the top layer to move) this electric field means that the freely flowing electrons have the energy to move towards where there is a positive charge.

(3). So, if we make a highway for them to travel on (let’s say a copper wire), the electrons can move towards the positive charge. And while they are moving towards this positive charge we can get them to do work for us, like powering a lightbulb.

Aotea Mānuka Oil Distillery Blueprint

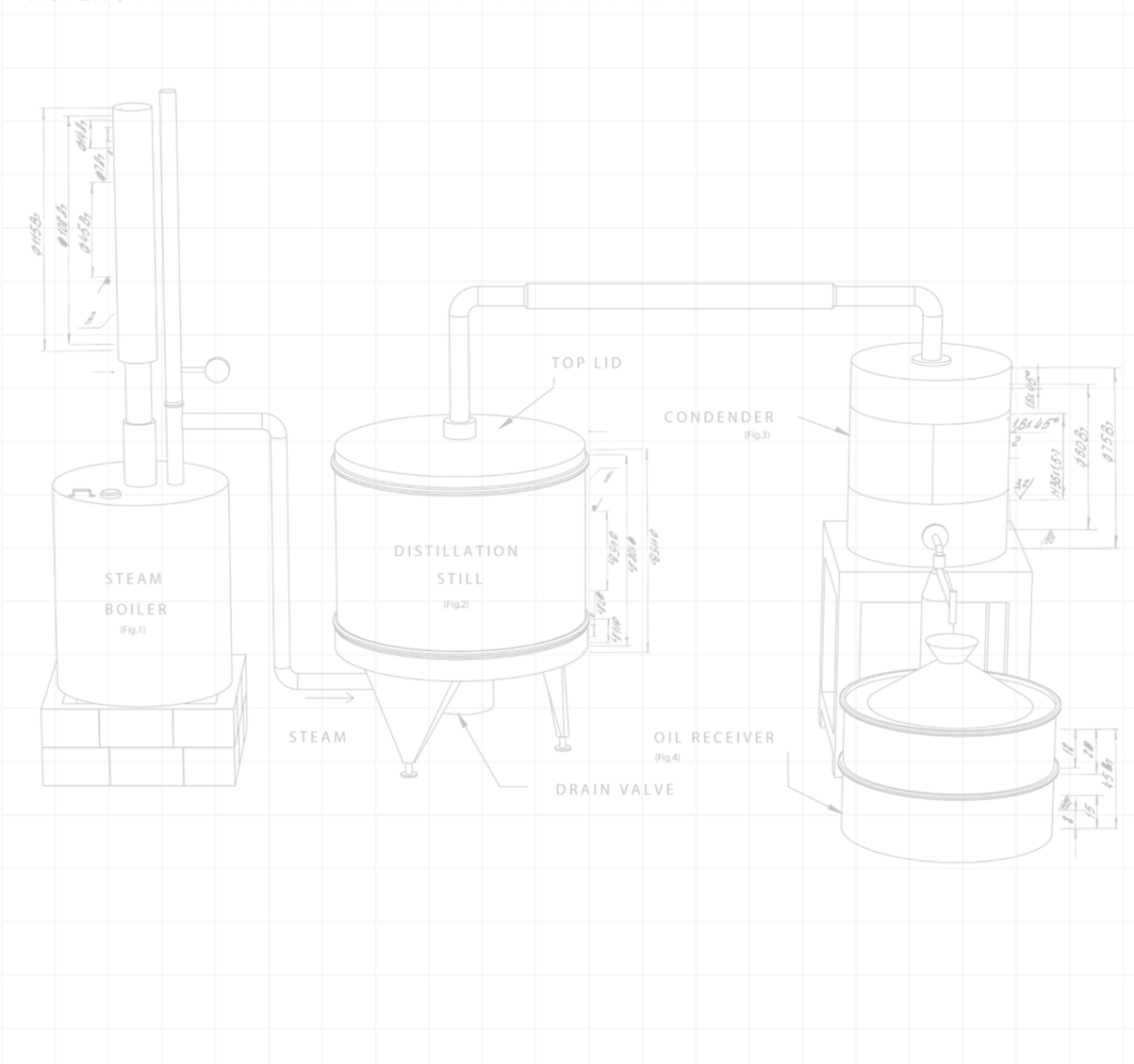

We are proud to say that we do all of our extraction and formulation on Aotea. Consequently, we have engineered and built our own mānuka oil distillery. Our blue prints are below.

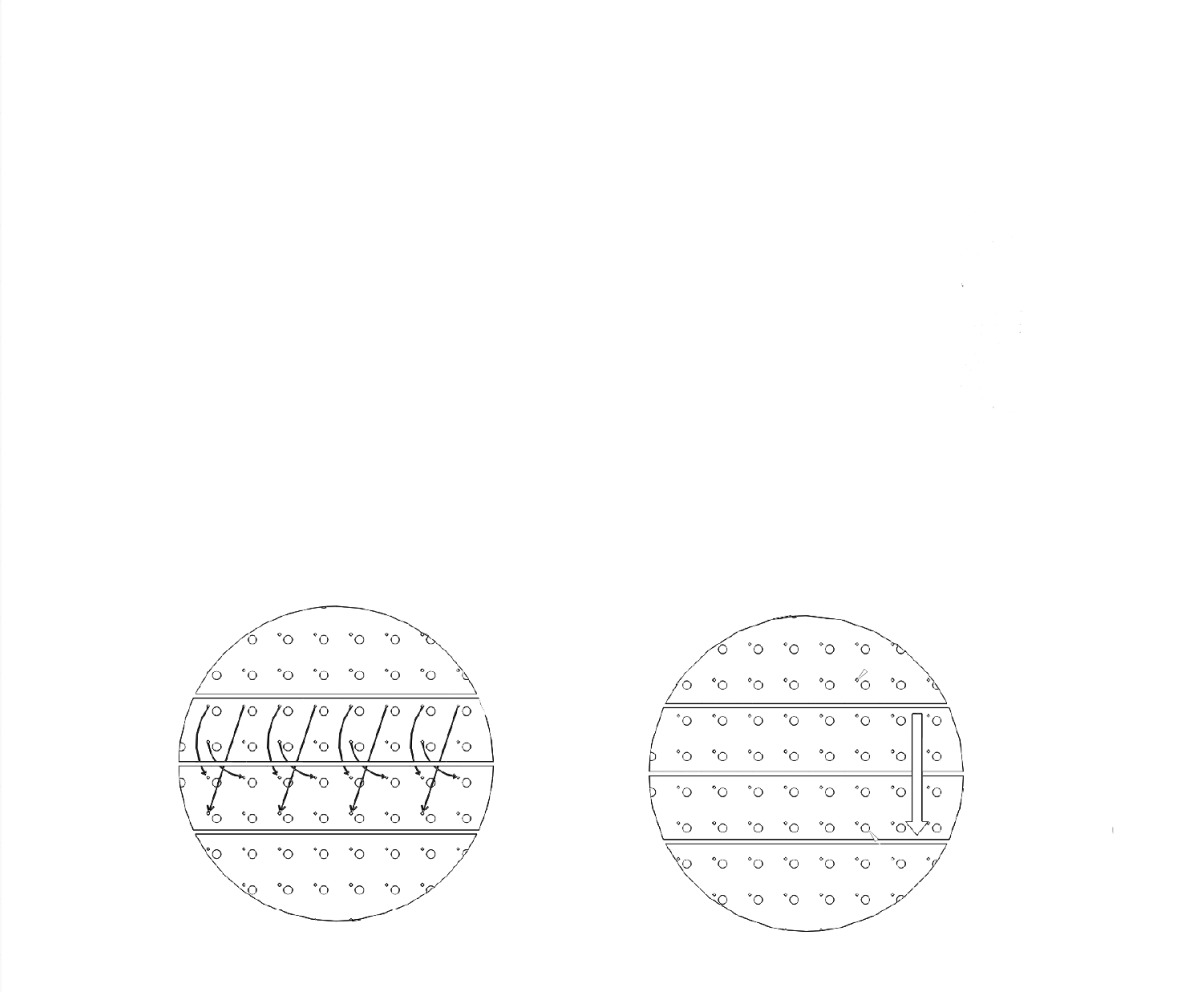

Fig (2) --- The steam rushes through the gate and flows into the basket (annotated on the diagram as the distillantion still). The basket is what holds the biomass / mānuka. On each mānuka leaf there are tiny little glands, or sacks of oil. Once the steam from the boiler hits the leaves held in the basket, these little glands / sacks of oil pop, to release the oil as a vapour.

Fig (1) --- The boiler is powered by a wood fire. The fire heats the water in the boiler; the water starts to

create steam. Once we have enough pressure in the boiler we release the steam through the gate at the

top of the boiler.

Fig (2) --- The steam rushes through the gate and flows into the basket (annotated on the diagram as the distillantion still). The basket is what holds the biomass / mānuka. On

each mānuka leaf there are tiny little glands, or sacks of oil. Once the steam from the boiler hits the leaves held in the basket, these little glands / sacks of oil pop, to release the oil as a vapour.

Fig (4) --- Once the mānuka oil and mānuka hydrosol enter the separation column, because the oil is lighter than water, it sits above the hydrosol and we siphon the oil off and collect it

from the valve at the top of the separation column.